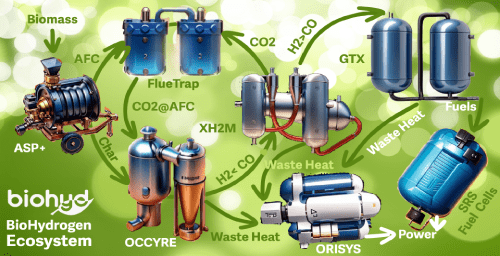

Like putting together piece by piece in a big puzzle, the final piece in the biohydrogen technology ecosystem is the technology that we introduced as SRS (Steam Reforming and Shift) a few days ago in this media (https://lnkd.in/gtmKHhfN). In total there are 7 technologies related to biohydrogen, and I explain the role of each below.

The first is Autothermal Slow Pyrolyzer (ASP) technology, its function is to convert all forms of biomass from rubbish and waste into charcoal, from rubbish and waste which was originally a liability it will turn into an asset in the form of stored energy reserves, which can be used anywhere, anytime.

This charcoal becomes feedstock for syngas production with the OCCYRE (Onboard Carbon Cycles for Regenerative Energy) reactor. Charcoal that is reacted with CO2 will become CO gas. Where does the CO2 come from? from subsequent carbon capture processes or from other emission sources captured using a third technology that we call FlueTrap. To capture CO2 emissions, we use an adsorbent in the form of AFC (Activated and Functionalized Carbon), which is also produced using the first technology, namely ASP, the ASP technology which we have equipped with the function for AFC production we call ASP+.

Some of the CO gas becomes feedstock for the next technology which we call XH2M (Extra High Hydrogen and Membrane), through XH2M this CO is processed into H2 and CO2. The CO2 is then recaptured again with a FlueTrap for subsequent regenerative H2 production. Meanwhile, the H2 produced by XH2M is combined with CO to be fed to the fifth technology which we call GTX, to become hydrocarbons like gasoline, diesel and LPG.

Up to this point we can produce all the types of fuel we need today, but we can also take extra miles for advanced energy efficiency. So the sixth technology was born which we call ORISYS (Organic Rankine System), whose function is to capture waste heat from OCCYRE, XH2M and GTX, and convert it into electricity, so we can get cheap electricity from this waste heat.

Then the seventh technology that I mentioned at the beginning of this article, we call it SRS (Steam Reforming and Shift), its function is so that the hydrocarbon fuel produced by the GTX mentioned above can be used more efficiently. SRS Fuel Cells, like other fuel cell technologies, have an efficiency level of more than 50%, while Internal Combustion Engine (ICE) engines are generally only in the range of 25% to 30%.

This biohydrogen technology ecosystem is now ready to be collaborated in part or in full with corporations and institutions throughout the world that need this clean and affordable energy, to accelerate ESG, SDGs and decarbonization targets